As the saying goes: “A good saddle goes well with a horse”, the power source of FEEGOO hand dryer is configured exactly what the current situation is — brushless motors, as we all know, large and small brushless motors are used in many In the field of artificial intelligence (AI). So where is the use of the brushless motor of the hand dryer? Here is the answer for everyone:

ECO9966 hand dryer with frequency conversion brushless motor.

First : Brushless motor characteristics

The brushless DC motor is composed of a motor body and a driver, and is a typical mechatronic product. Since the brushless DC motor runs in a self-control mode, it will not add a start winding to the rotor like a synchronous motor that is started under heavy load under variable frequency speed regulation, nor will it cause oscillation and out-of-step when the load changes suddenly. The permanent magnets of medium and small capacity brushless DC motors are now mostly made of rare earth neodymium iron boron (Nd-Fe-B) materials with high magnetic energy product. Therefore, the volume of the rare earth permanent magnet brushless motor is one size smaller than that of the three-phase asynchronous motor of the same capacity. In general, it is small in size and high in power.

Second : The difference between brushless motor and brush motor

When a brushed motor works, the coil and commutator rotate, but the magnet and carbon brushes do not rotate. The alternating current direction of the coil is changed by the commutator and brushes that rotate with the motor. In the electric vehicle industry, brush motors are divided into high-speed brush motors and low-speed brush motors.

- High friction and high loss

Professional friends have encountered this problem when playing with brushed motors before, that is, after using the motor for a period of time, the motor needs to be turned on to clean the carbon brush of the motor, which is time-consuming and laborious, and the maintenance intensity is no less than a home cleaning.

2. High heat generation and short life span

Due to the structure of the brush motor, the contact resistance between the brush and the commutator is very large, which causes the overall resistance of the motor to be large and easy to generate heat. The permanent magnet is a thermal element. If the temperature is too high, the magnet will demagnetize , The performance of the motor is reduced, and the service life of the brushed motor is affected.

3. Low efficiency and low output power

The heat problem of the brushed motor mentioned above is largely due to the fact that the current is done on the internal resistance of the motor, so the electrical energy is converted to heat to a large extent, so the output power of the brushed motor is not high and the efficiency is not high.

Advantages of brushless motors

The brushless DC motor is composed of a motor body and a driver, and is a typical mechatronic product. Because the brushless DC motor operates in a self-controlled manner

1. No brush, low interference

The brushless motor removes the brush, and the most direct change is that there is no electric spark generated when the brush motor is running, which greatly reduces the interference of the electric spark to the remote control radio equipment.

2. Low noise and smooth operation

The brushless motor has no brush, the friction is greatly reduced during operation, the operation is smooth, and the noise is much lower. This advantage is a huge support for the stability of the model.

3. Long life and low maintenance cost

Without the brush, the wear of the brushless motor is mainly on the bearing. From a mechanical point of view, the brushless motor is almost a maintenance-free motor. When necessary, only need to do some dust removal maintenance. Comparing the previous and the next, we know the advantages of brushless motors over brushed motors, but everything is not absolute. The performance characteristics of brushless motors such as excellent low-speed torque performance and large torque are irreplaceable for brushless motors, but In terms of the ease of use of brushless motors, with the decreasing cost of brushless controllers and the development and market competition of brushless technologies at home and abroad, brushless power systems are in the stage of rapid development and popularization, which also greatly promotes The development of the model movement.

Third, the competition of various performance indicators

1. Scope of application:

Brushless motor: usually used in equipment with relatively high control requirements and high speed, such as aircraft models, precision instruments, etc., which have strict control of motor speed and high speed.

Carbon brush motors: usually power equipment uses brush motors, such as hair dryers, factory motors, household range hoods, etc. In addition, the speed of the series motor can reach very high, but due to the wear of the carbon brushes, use Life is not as good as brushless motors.

2. Service life:

Brushless motors: Usually the service life is in the order of tens of thousands of hours, but the service life of brushless motors is also very different due to different bearings.

Carbon brush motor: Generally, the continuous working life of a brush motor is several hundred to more than 1,000 hours. The carbon brush needs to be replaced when the use limit is reached, otherwise it is easy to cause the wear of the bearing.

3. Use effect:

Brushless motor: usually digital frequency conversion control, strong controllability, from a few revolutions per minute to tens of thousands of revolutions per minute can be easily achieved.

Carbon brush motor: The old carbon brush motor generally works at a constant speed after startup, and the speed adjustment is not very easy. The series motor can also reach 20,000 rpm.

But the service life will be shorter.

4. Energy saving:

Relatively speaking, the brushless motor controlled by inverter technology will save much energy than the series motor. The most typical ones are inverter air conditioners and refrigerators.

5. In terms of future maintenance, the carbon brush motor needs to be replaced. If it is not replaced in time, the motor will be damaged. The brushless motor has a long service life, usually more than 10 times that of the brush motor, but it needs to be replaced if it is broken. Motor, but daily maintenance is basically not needed.

6. The noise aspect has nothing to do with whether it is a brushed motor, but mainly depends on the matching of the bearing and the internal components of the motor.

The parameter index of the model brushless motor, in addition to the dimensions (outer diameter, length, shaft diameter, etc.), weight, voltage range, no-load current, maximum current and other parameters, there is also an important index–KV value, which is A unique performance parameter of the brushless motor is an important data for judging the performance characteristics of the brushless motor.

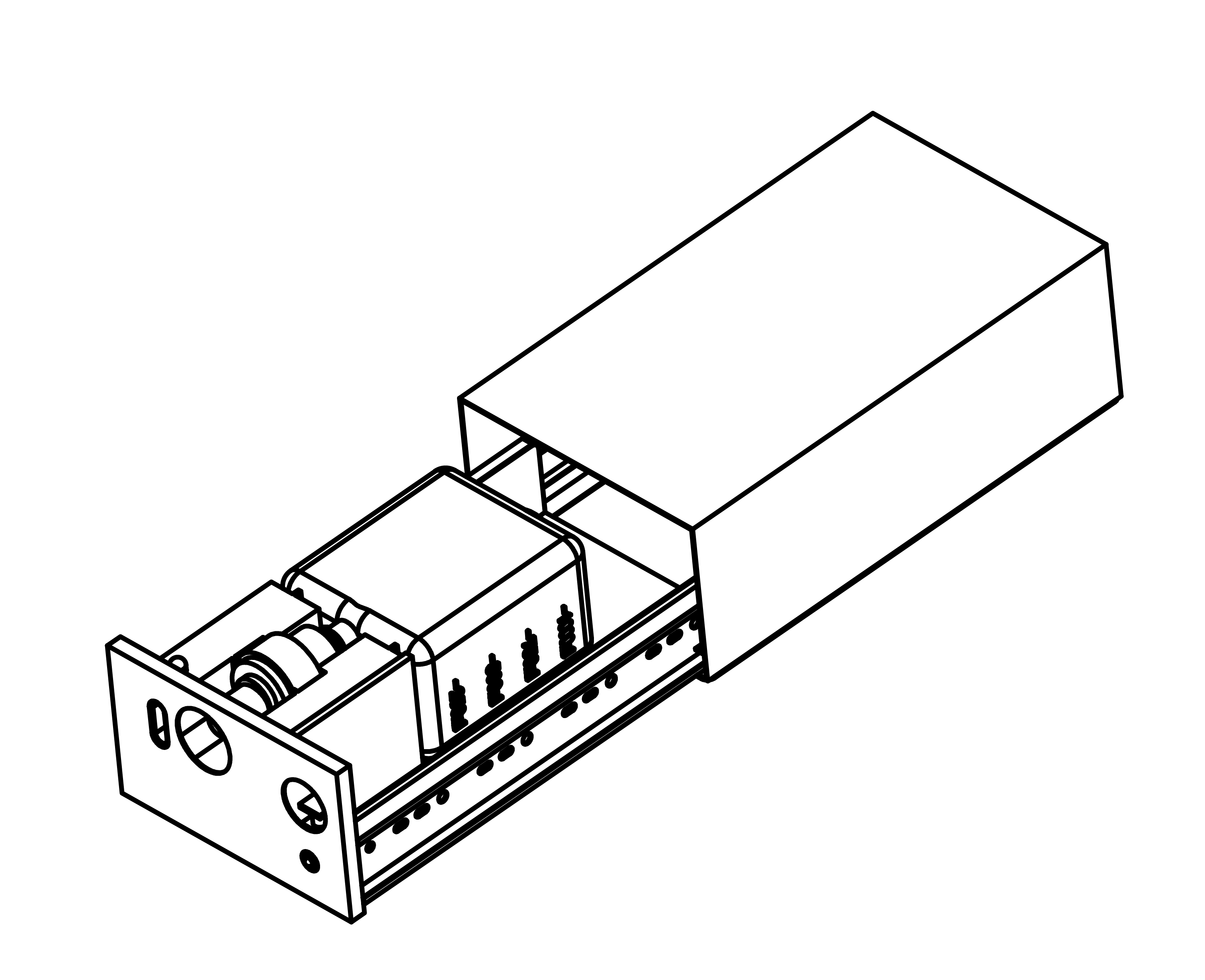

(FEEGOO) What is the brushless motor used in the air-jet hand dryer researched by Feegoo Technology?

principle:

① The brushless motor adopts electromagnetic steering and does not make any contact with the rotor.

② The carbon brush motor uses the rotation of the rotor, the brush is always rubbed with the commutation ring, and spark erosion occurs at the moment of commutation, so the brush is a vulnerable part in the entire motor. At the same time, some fine dust will be generated during friction with the rotor.

1.Scope of application:

Brushless motors: dairy products industry, brewing industry, meat product processing industry, soy product processing industry, beverage processing industry, pastry processing industry, pharmaceutical industry, electronic precision factory, and other dust-free workshops with higher requirements.

Carbon brush motor: It can only be used in all kinds of toilets and other areas where the requirements are not too high, but it cannot be used like a dust-free workshop!

2. Service life:

Brushless motor: It can work continuously for about 20,000 hours, and the conventional service life is 7-10 years.

Carbon brush motor: It can work continuously for about 500 hours, and the conventional service life is 2-3 years.

3. Use effect:

Brushless motor: It runs at a high speed of 90-95m/s, and the actual effect can reach the myth of dry hands in 5-7s.

Carbon brush motor: the running speed and dry time are much lower than the brushless motor.

4. Energy saving:

Relatively speaking, the power consumption of a brushless motor is only 1/3 of that of a carbon brush.

5. In terms of future maintenance, when the carbon brush motor is worn out, not only replace the carbon brush, but also replace the accessories around the motor such as the rotating gear. The cost is much higher. The most important thing is that the overall function will be affected.

6. The noise of carbon brush motors is much higher than that of brushless motors.

7. The repair rate of our brushless motor series products is within 1%, while the repair rate of carbon brush products is relatively much higher.

Post time: Aug-28-2021